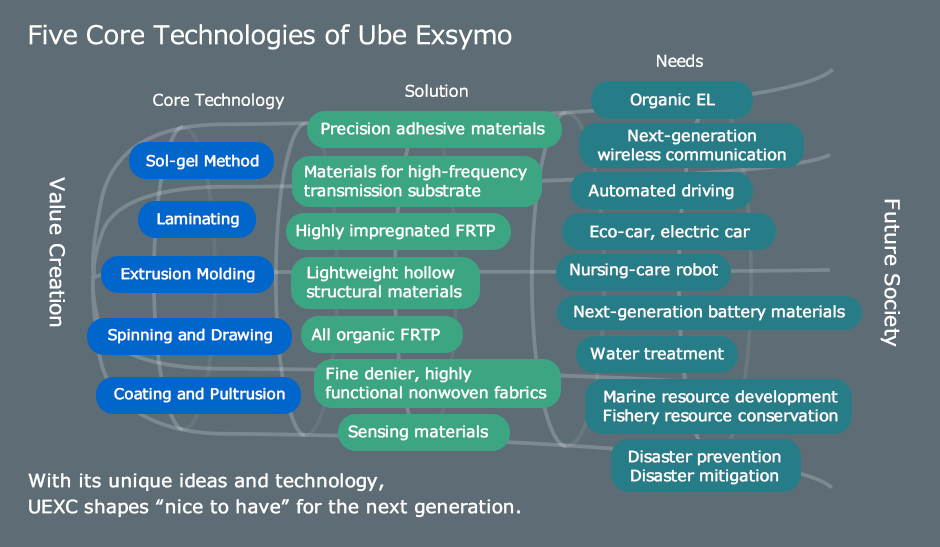

A half-century ago, our researchers’ passion for creating products from their unique ideas bore fruit in the establishment of olefin resin extrusion molding technology which leads to the completion of the world’s first packing polypropylene band and brought revolution to the logistics industry when paper bands and band irons were major.

The extrusion molding technology further evolved while adding such technical elements as various forms of cross section, precision, and rotation. It applies to spacers with spiral grooves to accommodate optical fibers, a means for optical communication networks running through every corner in Japan, thus supporting the IT infrastructure. The five core technologies introduced here are all unique to UEXC. We will continue to excel our technology and to shape “nice to have” for the next generation.

Hollow Structure Board "TWINCONE"

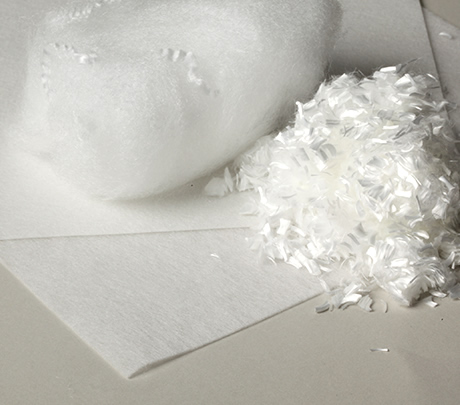

Hollow Structure Board "TWINCONE" Staple fiber of SIMTEX

Staple fiber of SIMTEX Three-layer structure by special resin adhesive

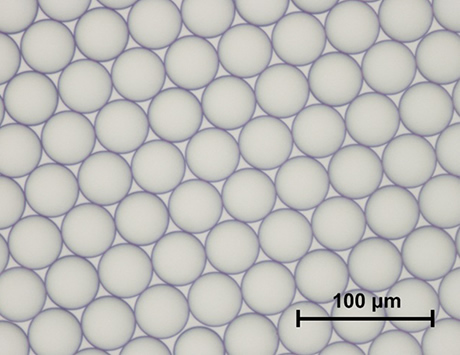

Three-layer structure by special resin adhesive Electron microscope image of HIPRESICA (diameter particle:40μm)

Electron microscope image of HIPRESICA (diameter particle:40μm) Photograph of CFRTP cross-section

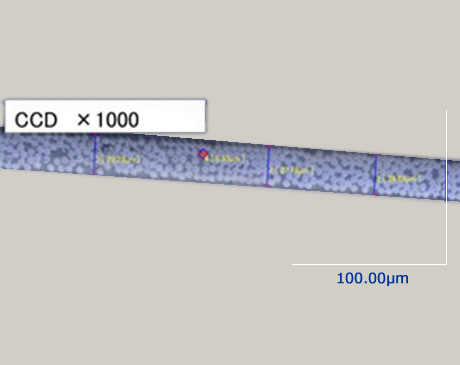

Photograph of CFRTP cross-section